Propeller Polishing

Propeller Polish

How Many Times have you seen a dive report stating: Propeller polished from Rubert E to Rubert A Grade? And I am sure you have often asked yourself, how the heck does the diver know that? He doesn’t, he just say it as everyone does! Unless polishing is done for several days the above is simply impossible.

In IMS we have put science behind this all, working close with professor Sverre Steen at NTNU in Trondheim, Norway. Findings are as follows: During a Polishing say 4-6 Hrs. maximum achievement is 2 grades, for instance C to A, or more likely D to B or even E to C. However if really the increase in 2 grades is achieved, for a typical 14 knot Panamax Tanker/Bulker you should have an increase in speed of 0.3 – 0.5 knots ! (at the same consumption).

Research and development have made us able to delver a very high quality propeller polishing, and as our many clients already know, we operate on a no cure no pay basis. We do not sell Cleaning and Polishing WE SELL INCREASED PERFORMANCE. (Still today we have not lost a penny on our philosophy).

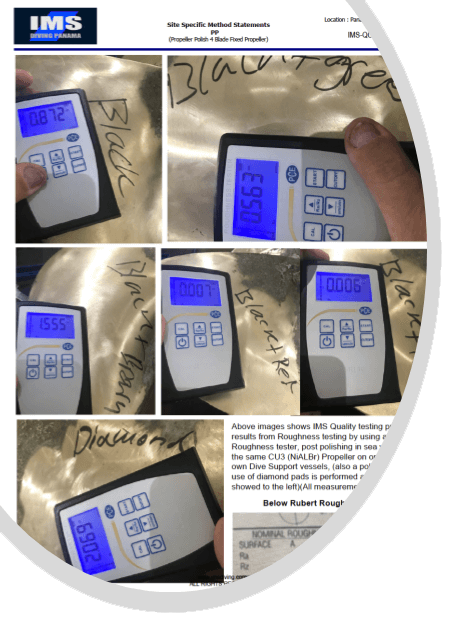

We do measure all Polishing before and after by use of a Roughens meter. We have also developed a Rule of Thumb for our underwater THE PROPELLER BLADE (MIRROR) YOU HAVE NO RUBERT A AT ALL!!

Trough systematic training of our uw techs we have been able to develop a safe routine which trough roughness verification is guaranteeing the highest Rubert Grade achievable for their propeller

Propeller Polish

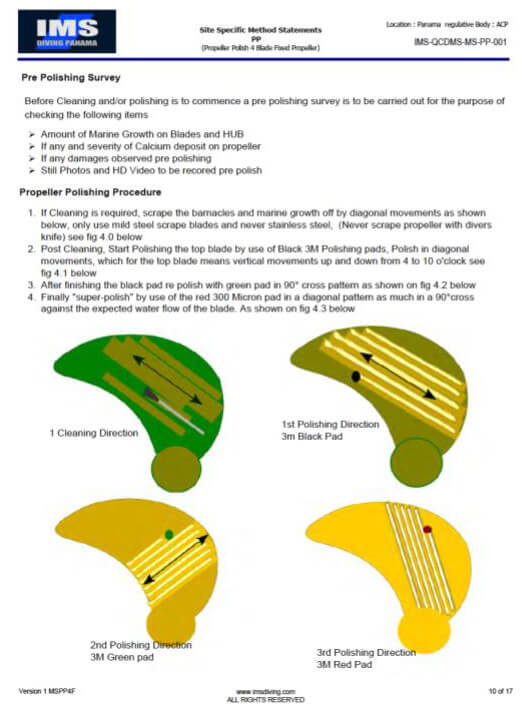

As in everything, and particularly in propeller treatment “the devil is in the details” We in IMS has tested all kinds if underwater polishing methods and pads and found that the best results (by far) are achieved by using Russian (pre cold war) Submarine propeller Polishing Pads. Since the examples we got years ago from Russia are no longer produced, we have made our own production of those pads by a reputable factory in China.

To the right you can see and extract of IMS “Propeller Polishing Job Description” where the selection and choice of polishing pads are described.

Further we have found that RPM for the polishing machines, especially during the final super polishing are very important, any RPM below 870 we have fount not sufficient to reach a Rubert A grade, the best results are achieved above 2200 rpm.

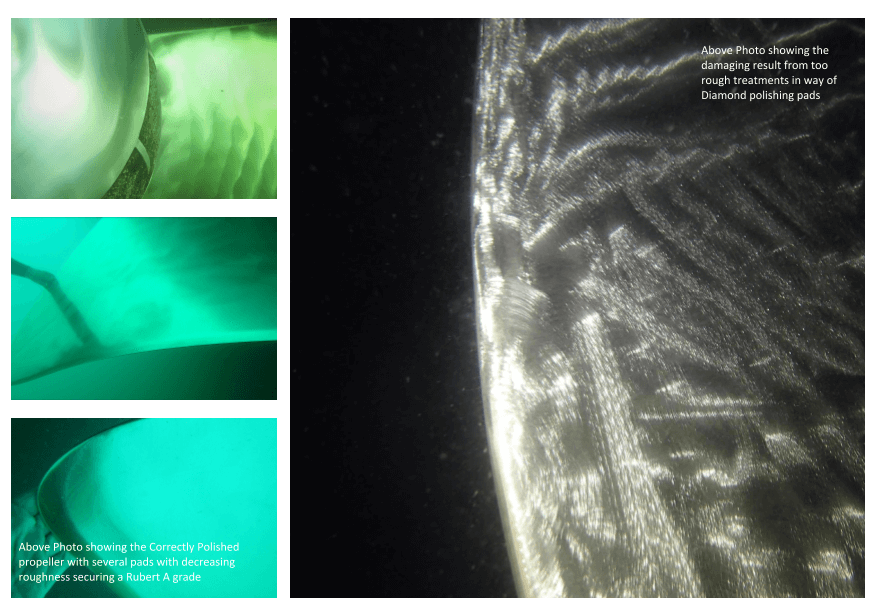

Unfortunately some underwater contractors has lately been using rough stones and even diamond pads on propellers, this has caused severe damaged to many propeller which will now take years of polishing to ever recover (if ever) Using a diamond cutter against bronze is like using a steel brush on gauda cheese. Below you can see images taken after both correctly and incorrectly use of polishing pads.

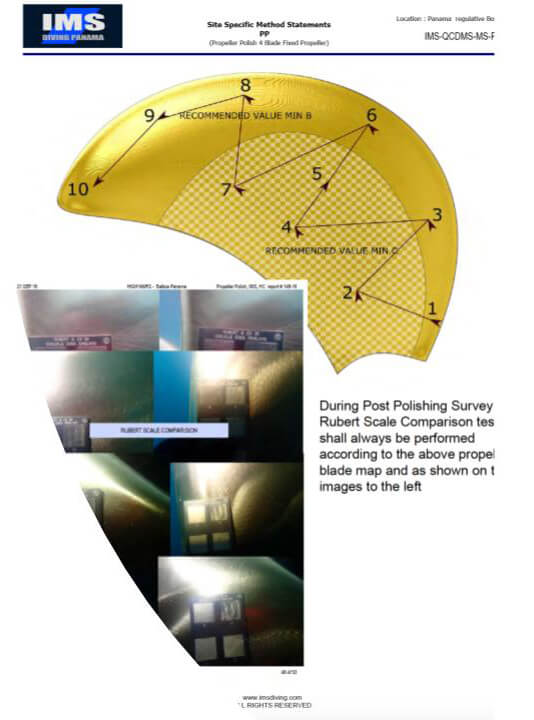

Post Propeller Polish we do perform a detailed Rubert scale testing and comparison, often when time permits, we also use our PCE roughness tester to confirm the achievements of Rubert A Grades. We as well as other dive companies that has done this research and developments knows how difficult it really is to achieve a good Rubert A A or even B grade, but the companies that has done this may be counted on one hand. (on two fingers only)

The method used for propeller polishing is always important, by variating the angle of the polishing directions we have found that the best results are obtained, to the right is an extract of our propeller job description.

Propeller Polish Identification

After years of training and educations our uw techs are now aware of the different areas of the propeller, leading & trailing edges , suction & pressure sides etc, and the importance of threating all these area the correct way. Unlike any other UW service providers we have observed, we identify each propeller blade with cards so that all photos and videos are easily identifiable.

Correct identification of propeller blades before and after polish is imprtant